NEUMAIER INDUSTRY – Ihr Partner für industrielle Lösungen.

Referenzen: Routenzüge, Fahrerlose Transportsysteme (FTS), Outdoor-FTS

Neugart GmbH

Deutsche Bahn Werk Krefeld

Liebherr-Werk Ehingen GmbH

Bergbahnen Sölden

Siemens Mobility Gmbh Werk Krefeld

ZF Group - ZF Airbag Germany GmbH Laage

AMKmotion GmbH + Co KG

Daimler Truck AG Werk Kassel

Liebherr-Werk Bischofshofen GmbH

KIEFEL GmbH

HUESKER Synthetic GmbH

Europa-Park GmbH & Co Mack KG / Rulantica

HYDRO Systems KG

Deutsche Bahn Werk Krefeld

Huber+Suhner AG

Hauff-Technik GmbH & Co. KG

Tyrolit – Schleifmittelwerke Swarovski AG & Co K.G, Schwaz, AT

Daimler Truck AG Werk Rastatt

nobilia-Werke J. Stickling GmbH & Co. KG.

Roche Holding AG

Mercedes Benz Werk Mettingen

elobau GmbH & Co. KG

Deutz AG Werk Herschbach

Hereaus Deutschland GmbH & Co. KG

Ehret GmbH

John Deere Werk Zweibrücken

John Deere Werk Zweibrücken

Horsch Maschinen GmbH

Horsch Leeb Application Systems GmbH

Unternehmen in Österreich

Conductix-Wampfler GmbH

Pöppelmann GmbH & Co. KG

Mercedes Benz AG Werk Untertürkheim

Dethleffs GmbH & Co. KG

Schnellecke Logistics SE

Vorwerk SE & Co. KG

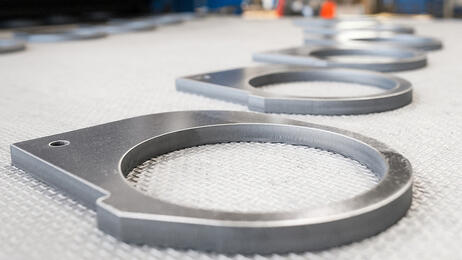

a.i.m. all in metal GmbH

Pilatus Flugzeugwerke AG

Horsch Leeb Application Systems GmbH

SAME DEUTZ-FAHR Deutschland GmbH

Mercedes-Benz Werk Gaggenau

Grünbeck AG

Reiashauer AG

GRAMMER System GmbH

BLG Industrielogistik GmbH & Co. KG

Mercedes-Benz Werk Gaggenau

Roto Frank AG

Ab 2027: Autonomer People-Mover CITY TRAIN

Automatisierter People-Mover CITY TRAIN

Der CITY TRAIN ist ein fahrerloses Personenbeförderungsfahrzeug für den öffentlichen Nahverkehr mit dem Automatisierungs-Level 4. Das Fahrzeug übernimmt auf vordefinierten Fahrstrecken (spezifischer Anwendungsfall) alle Fahraufgaben selbstständig und überwacht vollständig und permanent seine Umgebung.

- Fahrerloses und eigenständiges Fahren in vordefinierten Bereichen

- Permanente und vollständige Rundum-Safety-Überwachung

- Barrierefreie Passagierkabinen für alle Gesellschaftsgruppen

- Mehrgliedriger Zugverbund für beste Manövrierbarkeit, Wendigkeit und Flexibilität

- Bis zu 5 Passagierkabinen für 60 Personen

Erfahren Sie hier bald mehr über den vollautomatisierten People-Mover CITY TRAIN.

Videos / Einsatzreportagen von Routenzügen und Fahrerlosen Transportsystemen FTS

Liebherr Bischofshofen beliefert Montage mit Industry Train Routenzug

Routenzug Industry Train bei Hauff-Technik in Hermaringen

Grammer automatisiert Intralogistik mit Neumaier AGV-Lösung Factory Shuttle FS400

Factory Train Routenzug erfüllt Elobau-Anforderungen zu 100%

SCHNELLECKE beliefert BMW mit 8 Factory Train Routenzügen

ZF-TRW macht Intralogistikversorgung mit Routenzug Factory Train

SAME DEUTZ-FAHR beliefert Montagelinie mit Factory Train Routenzug

DETHLEFFS produziert Wohnwagen/-mobile mit Neumaier Routenzug

BERGBAHN SÖLDEN fährt Neumaier Routenzug unter der Skipiste

PILATUS Flugzeugbau mit Factory Train Routenzug

TADANO FAUN hat zwei Neumaier Routenzüge für In- und Outdoor

EHRET transportiert Fensterläden mit Routenzug Factory Train

WAFA versorgt Produktion mit Neumaier Routenzug

MAN Truck & Bus beliefert Produktion mit Neumaier Routenzügen

KUKA Augsburg hat Factory Train Routenzug im Einsatz

KEMMLER transportiert Baustoffe mit Factory Train Routenzug

Aktuelles

-

LogiMAT 2026 vom 24.-26. März – NEUMAIER INDUSTRY

Besuchen Sie uns auf der LogiMAT 2026 in Halle 10, Stand G31. -

NEU: Autonomer Gabelstapler FE600 für In- und Outdoor

Automatisieren Sie Ihre Intralogistik und senken Sie Ihre Kosten. -

Outdoor Routenzug Baureihe Factory Train FT800

Intralogistik: Sichere und wirtschaftliche innerbetriebliche Materialtransporte Indoor und Outdoor