Performances in system engineering

Project planning, development and design construction

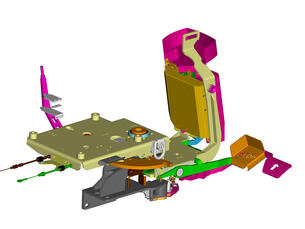

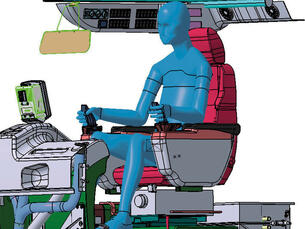

Mechatronic products are complex systems, where mechanical, electrical, pneumatic and data processing components are integrated and must harmonize with each other optimally. Good preliminary planning is therefore essential. We therefore plan every customer enquiry and own development at the project stage first of all and check it for feasibility. Only then does the real development and design construction kick off, which is carried out in close collaboration with our customers.

Our development department works with the 3D-CAD programme PRO ENGINEER to design mechatronic products. All individual parts and components are designed step by step in this way and combined to a finished mechatronic product.

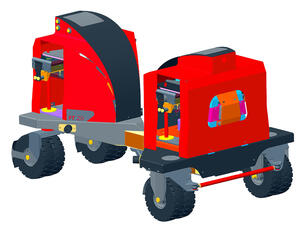

Prototype construction and test runs

After the development and design construction are completed and all the components of the mechatronic product exist constructively, prototypes can be produced and test runs carried out. With our own sheet metal processing department in the company all the sheet metal parts can be manufactured rapidly, flexibly and with great precision.

The prototype is checked and tested intensively using standardized test procedures and series of tests. Special attention is paid here primarily to functionality, stability, processing and of course safety-related aspects. Improvements and optimizations are implemented and tested directly on the prototype.

We act as manufacturer in the manufacture of mechatronic systems. Required tests and approvals are carried out and obtained by us according to EC guidelines and the product produced until it is ready to go on the market and into mass production.

Production and assembly

Production and assembly is carried out entirely in our factory. Our own sheet metal processing department produces all the sheet metal parts from simple sheet metal cuts to complex welding structural components. Our modern equipped assembly halls enable us to produce both flexible single-items and a precisely timed mass production of medium to large numbers.

Documentation and delivery

Depending on the complexity and type of mechatronic product, detailed documentation such as operating instructions, maintenance manuals and spare parts documentation are compiled and delivered together with the product. The punctual delivery to our customers is carried out either by our own truck fleet or with carriers – depending on the scope and customer agreement.